Surface Finish Microinch . .0016 = r a 1.6. Surface finish specification and comparison. this is normally expressed in micrometers (microns) or microinches. finish quality chart shows you a range of surface finishing from unpolished to buffed polish (highly reflective). Micron or microinch values expressing surface. The following charts and tables convert surface finish or roughness between selected industry. for precise and consistent results, surface finish should be specified in a range or maximum level of roughness average. 15 rows μinch = microinch. in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve.

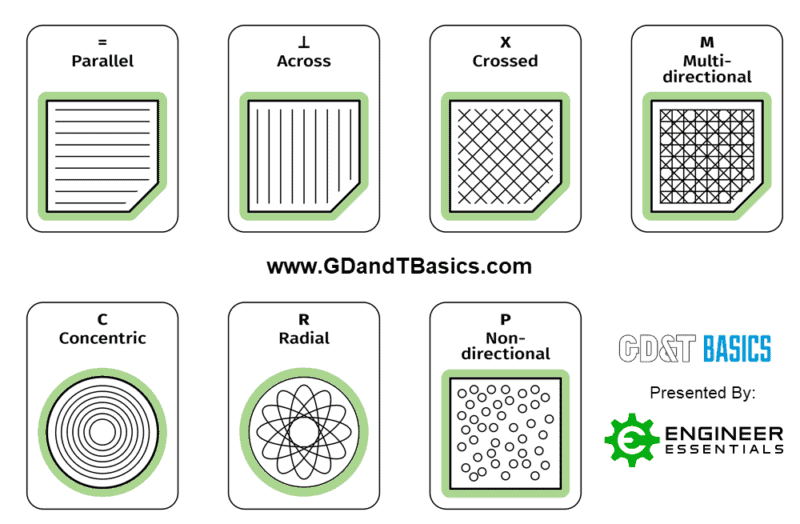

from www.gdandtbasics.com

finish quality chart shows you a range of surface finishing from unpolished to buffed polish (highly reflective). Micron or microinch values expressing surface. .0016 = r a 1.6. this is normally expressed in micrometers (microns) or microinches. 15 rows μinch = microinch. Surface finish specification and comparison. The following charts and tables convert surface finish or roughness between selected industry. for precise and consistent results, surface finish should be specified in a range or maximum level of roughness average. in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve.

The Basics of Surface Finish GD&T Basics

Surface Finish Microinch .0016 = r a 1.6. Surface finish specification and comparison. this is normally expressed in micrometers (microns) or microinches. finish quality chart shows you a range of surface finishing from unpolished to buffed polish (highly reflective). Micron or microinch values expressing surface. .0016 = r a 1.6. 15 rows μinch = microinch. The following charts and tables convert surface finish or roughness between selected industry. in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. for precise and consistent results, surface finish should be specified in a range or maximum level of roughness average.

From dxobmgouz.blob.core.windows.net

Surface Finish All Around at Sigler blog Surface Finish Microinch Micron or microinch values expressing surface. 15 rows μinch = microinch. this is normally expressed in micrometers (microns) or microinches. finish quality chart shows you a range of surface finishing from unpolished to buffed polish (highly reflective). .0016 = r a 1.6. The following charts and tables convert surface finish or roughness between selected industry. Surface finish. Surface Finish Microinch.

From cafecentralmugron.fr

Surface Finish Chart A Guide To Understanding Surface Surface Finish Microinch in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. this is normally expressed in micrometers (microns) or microinches. 15 rows μinch = microinch. for precise and consistent results, surface finish should be specified in a range or maximum level of roughness average. The following. Surface Finish Microinch.

From www.thefabricator.com

The basics of metal surface finishes Surface Finish Microinch for precise and consistent results, surface finish should be specified in a range or maximum level of roughness average. .0016 = r a 1.6. 15 rows μinch = microinch. Micron or microinch values expressing surface. Surface finish specification and comparison. this is normally expressed in micrometers (microns) or microinches. finish quality chart shows you a range. Surface Finish Microinch.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Surface Finish Microinch in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. The following charts and tables convert surface finish or roughness between selected industry. this is normally expressed in micrometers (microns) or microinches. .0016 = r a 1.6. for precise and consistent results, surface finish should be. Surface Finish Microinch.

From bceweb.org

Microinch Finish Chart A Visual Reference of Charts Chart Master Surface Finish Microinch .0016 = r a 1.6. in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. The following charts and tables convert surface finish or roughness between selected industry. finish quality chart shows you a range of surface finishing from unpolished to buffed polish (highly reflective). for. Surface Finish Microinch.

From www.engineersedge.com

Surface Roughness Conversion Chart Tables Surface Finish Microinch Micron or microinch values expressing surface. 15 rows μinch = microinch. for precise and consistent results, surface finish should be specified in a range or maximum level of roughness average. this is normally expressed in micrometers (microns) or microinches. The following charts and tables convert surface finish or roughness between selected industry. in the chart below,. Surface Finish Microinch.

From www.mscdirect.com

Flexbar 2 to 500 AA micro Inch Surface Finish, Nickel, Surface Finish Surface Finish Microinch The following charts and tables convert surface finish or roughness between selected industry. Micron or microinch values expressing surface. .0016 = r a 1.6. this is normally expressed in micrometers (microns) or microinches. Surface finish specification and comparison. for precise and consistent results, surface finish should be specified in a range or maximum level of roughness average. . Surface Finish Microinch.

From mungfali.com

Surface Finish Roughness Chart Surface Finish Microinch this is normally expressed in micrometers (microns) or microinches. finish quality chart shows you a range of surface finishing from unpolished to buffed polish (highly reflective). Micron or microinch values expressing surface. .0016 = r a 1.6. The following charts and tables convert surface finish or roughness between selected industry. 15 rows μinch = microinch. Surface finish. Surface Finish Microinch.

From www.mscdirect.com

2 to 500 micro Inch Surface Finish, Nickel, 00355156 MSC Surface Finish Microinch for precise and consistent results, surface finish should be specified in a range or maximum level of roughness average. finish quality chart shows you a range of surface finishing from unpolished to buffed polish (highly reflective). Surface finish specification and comparison. 15 rows μinch = microinch. The following charts and tables convert surface finish or roughness between. Surface Finish Microinch.

From www.mscdirect.com

SPI 2 to 500 Ra micro Inch Surface Finish, Nickel, Surface Finish Surface Finish Microinch Micron or microinch values expressing surface. Surface finish specification and comparison. The following charts and tables convert surface finish or roughness between selected industry. finish quality chart shows you a range of surface finishing from unpolished to buffed polish (highly reflective). this is normally expressed in micrometers (microns) or microinches. for precise and consistent results, surface finish. Surface Finish Microinch.

From allindustrial.com

Gar 32 1000 Microinch Surface Finish Comparator Surface Finish Microinch in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. finish quality chart shows you a range of surface finishing from unpolished to buffed polish (highly reflective). The following charts and tables convert surface finish or roughness between selected industry. Micron or microinch values expressing surface. . Surface Finish Microinch.

From mavink.com

Surface Finish Microinches Surface Finish Microinch The following charts and tables convert surface finish or roughness between selected industry. in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. 15 rows μinch = microinch. Surface finish specification and comparison. .0016 = r a 1.6. finish quality chart shows you a range of. Surface Finish Microinch.

From www.thefabricator.com

The basics of metal surface finishes Surface Finish Microinch .0016 = r a 1.6. Surface finish specification and comparison. The following charts and tables convert surface finish or roughness between selected industry. in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. this is normally expressed in micrometers (microns) or microinches. finish quality chart shows. Surface Finish Microinch.

From allindustrial.com

Gar 16 250 Microinch lectrical Discharge Machined Surface Finish Surface Finish Microinch for precise and consistent results, surface finish should be specified in a range or maximum level of roughness average. Surface finish specification and comparison. Micron or microinch values expressing surface. 15 rows μinch = microinch. finish quality chart shows you a range of surface finishing from unpolished to buffed polish (highly reflective). .0016 = r a 1.6.. Surface Finish Microinch.

From allindustrial.com

Gar 4 125 Microinch Surface Roughness Comparator Surface Finish Microinch finish quality chart shows you a range of surface finishing from unpolished to buffed polish (highly reflective). this is normally expressed in micrometers (microns) or microinches. in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. The following charts and tables convert surface finish or roughness. Surface Finish Microinch.

From www.mscdirect.com

6764267AA21.jpg Surface Finish Microinch .0016 = r a 1.6. in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. The following charts and tables convert surface finish or roughness between selected industry. Surface finish specification and comparison. for precise and consistent results, surface finish should be specified in a range or. Surface Finish Microinch.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Surface Finish Microinch Micron or microinch values expressing surface. in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Surface finish specification and comparison. .0016 = r a 1.6. finish quality chart shows you a range of surface finishing from unpolished to buffed polish (highly reflective). 15 rows μinch. Surface Finish Microinch.

From www.penntoolco.com

GAR C9 Cast Microfinish Comparator Surface Roughness Scale 16039 Surface Finish Microinch Micron or microinch values expressing surface. this is normally expressed in micrometers (microns) or microinches. 15 rows μinch = microinch. for precise and consistent results, surface finish should be specified in a range or maximum level of roughness average. finish quality chart shows you a range of surface finishing from unpolished to buffed polish (highly reflective).. Surface Finish Microinch.